Optimizing powder characteristics

More than 60 years of experience

Glatt has more than 60 years of experience in optimizing powder characteristics and will as your partner ensure fast and successful product development.

Test before procurement

In Glatt’s state-of-the-art technology centre in Germany, product ideas can be tested in laboratory scale and pilot scale, which ensures that performance will be met in production scale plants.

New technology

In 2015 Glatt introduced a new technology – the so-called Power Synthesis – for high-performance applications, which allows high-temperature processes for creating extremely homogeneous powder materials.

Glatt Process Technology Food, Feed & Fine Chemicals provides products, technology, and system expertise for the entire value chain, from particle design to industrial production. Focus is on powder synthesis and fluidized bed processes for developing, manufacturing, optimizing, and refining powders and bulk materials such as granules and pellets.

Particle design for generation, functionalization, and enhancement of granule properties

Get dust-free particles with defined properties like: Form, structure, particle and bulk density, specific surface area, hardness and resistance to abrasion, particle size and particle size distribution, dosing behavior, flow behavior, solubility, dispersibility, hygroscopicity, wettability, instant behavior, tabletability, release behavior, smell/taste, storage compatibility, visual attractiveness, sorption behavior, thermostability, chemical compatibility, oxidation compatibility, mechanical durability, multi-layer coating for graded functionality.

Chemical/fine chemical product examples:

Detergent components, enzymes, pesticides, ceramics, pigments, polymers, industrial salts, speciality fertilizers, bleaching agents, catalysts, special applications like diamonds.

Food and feed product examples:

Sweeteners, preservatives, texturants, instant drinks, soups, natural flavor extracts, herbs, oils, enzymes, probiotics, PUFA.

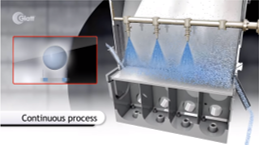

Fluid bed and spouted bed processes for the production of granules and pellets out of solid and/or liquid raw materials

You have nearly unlimited options in terms of optimized particle design and suitable functionalizations of granules.

The key to the ideal product is choosing the right process parameters, along with the multitude of combinations options for these parameters.

Spray granulation = granules and pellets from liquids

Spray agglomeration = granules from powder

Spray coating = encapsulation of particles with liquids

Spray encapsulation = (micro-)encapsulation of liquids

See a video of Glatt’s continuous granulation and coating by fluidized bed here

Glatt Powder Synthesis to generate high-performance powder materials

This unique spray calcination technology, allows to generate, coat and subsequently calcinate particles at temperatures from 200°C to >> 1000°C in one single process step.

- Complex stoichiometry and doped materials: Chemical and mineralogical composition configured with almost complete freedom

- Particles from high-temperature phases: Flexibly adjustable phase composition

- Customer-specific coatings and core-shell particles: Targeted surface functionalization

- Tailor-made shape, size, and spherical morphology: Precisely defined shape and particle structure

The exceptional thermodynamic conditions of Glatt Powder Synthesis offer limitless potential for the development of entirely new types of powder with defined properties. Application examples: Ceramic oxides, complex oxides, doped oxides, catalysts, pigments, battery materials, core-shells.

Process technology in Glatt’s Technology Center in Weimar/Germany for product and process development/engineering/optimization

Lab-scale

- Mini-Glatt for fluidized bed processes

- ProCell LabSystems for fluidized bed, spouted bed, and rotor processes

- Glatt ProAPP® reactors for powder synthesis

Pilot scale

- AGT PilotSystem for fluidized bed and rotor processes

- ProCell PilotSystem for fluidized bed and spouted bed processes

- Glatt ProAPP® reactors for powder synthesis

Production scale

- Glatt GVW vacuum fluidized bed system

- Glatt ProAPP® reactors for powder synthesis

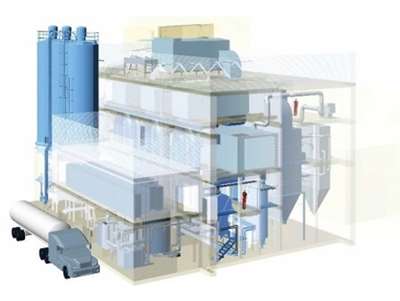

Process & Plant Engineering

Glatt combines professional engineering with in-depth technology expertise. Whether it be new construction, modernization, expansion or relocation of production sites – Glatt develops tailored integrated solutions that meet your specific needs.

Range of services

- Consulting and feasibility studies

- Conception, basic and detailed design

- Project management for planning and execution

- Government agency management and financing concepts

- Planning, management, supervision for construction, assembly, start-up

- EPCM projects

- Support with FAT and SAT

- After-sales-service

Feel free to contact us – we are ready to help you with fluid bed plants