Post-tensioning systems and soil anchors

Consultancy

Aage Christensen has more than 50 years of experience with selling soil anchors from Dywidag, and our experience can help you find the best solution.

Good quality

The soil anchors are manufactured in Germany with double corrosion protection and fulfil European standards.

Dywidag is a German manufacturer of post-tensioning systems and soil anchors which can be used for construction of everything from houses to bridges and wind turbines. The company with its headquarters in Munich can be dated back to 1865.

Anchoring systems

A soil anchor is a construction element used for anchoring of building structures such as:

- Uplift securing of underground cellars, tanks etc. in ground water

- Anchoring of bridges, masts, wind turbine foundations etc.

- Stabilization of slopes

- Anchoring of structural walls and excavations

- Anchoring of sheet pile walls

- Anchoring of dam structures

We deliver soil anchors of the highest quality

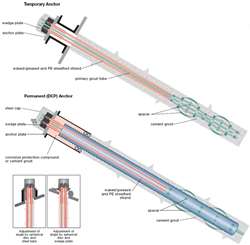

From Dywidag we can offer permanent anchors (DCP), temporary anchors, and electrically isolated anchors with threadbars or strands. Strand anchors are mainly used in case of very long anchors or very high anchor loads. Strand anchors can be delivered in rolls with or without pre-injection.

We can thus deliver the best soil anchors to you, whatever needs you may have.

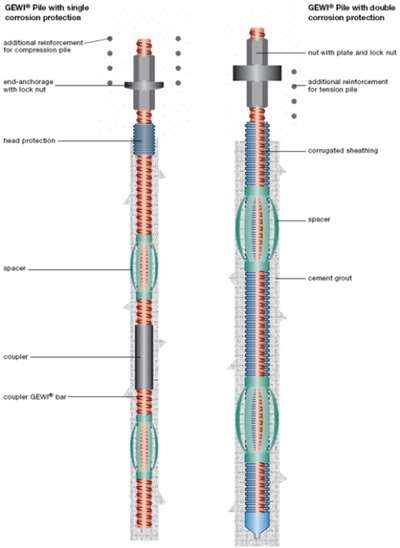

The Dywidag geotechnical systems, such as soil anchors, piles and soil nails with double corrosion protection (DCP), are manufactured according to German and other European standards. They fulfil the requirements in EN14199 (mini piles), EN1537 (soil anchors) and prEN14490 (soil nails) for permanent use. Based on this, a life time of more than 120 years can be expected, if the products are installed according to applicable norms and regulations.

Our soil anchors are built up and adapted especially to Danish conditions, where there often is a high ground water pressure. The anchors can be used in almost all kinds of soil conditions (rock, lime, moraine clay, gravel, sand, seabed etc.). The free length of the anchor and the bonded length are adapted to each project and proportioned according to the geotechnical report or test at the relevant location.

In the following links you will find detailed information about our anchors:

GEWI bars/anchor bolts

The GEWI System consists of GEWI bars (threadbars) and a broad variety of accessories.

The GEWI system is very suitable as:

- Tension rods for stabilizing of buildings

- Reinforcement steel in concrete

- Anchor bolts in harbour constructions

The GEWI bars can be delivered in dimensions ø12 – ø63.5 mm. The steel has a yield strength/ultimate strength of 500/550 N/mm.

The advantages of using GEWI steel are many. First of all the bars are made of steel 55 (Ultimate strength 550 MPa) and NOT of high strength steel. This is important for the corrosion of the bars, as the GEWI bars are as corrosion resistant as steel 52. The same applies for the dimension ø 63.5 mm which is made of steel 70.

For harbour constructions and anchoring of sheet pile walls with concrete dead weight blocks, the thread in the whole length is a major advantage as the bars can be shortened or extended according to the actual distance.

In addition to the normal GEWI bars with left-hand thread, DYWIDAG manufactures GEWI PLUS with right-hand thread in steel 670/800. The largest dimension is here 75 mm with an ultimate strength of 3534 kN.

The GEWI Piles are used as passive anchors, which can take both tensile and compressive loads as opposed to smooth concrete piles. As load transfer elements both GEWI and GEWI PLUS are used which have a max. diameter of 75 mm. As these piles are placed in drilled holes, noise and damages on nearby buildings are avoided.

Stressed reinforcement

Post-tensioning systems with bars

DYWIDAG’s post-tensioning systems consist of a complete programme of strands, bars and accessories for pre-stressing of concrete and geotechnical constructions.

This system is very well-documented and has been used for more than 90 years all over the world.

Threadbars

DYWIDAG’s threadbars are manufactured in high tension steel with a yield/ultimate strengh of 950/1050 N/mm2 (see “New steel quality” under “Dimensions for bar anchors”) in the dimensions ø 26.5, 32, 36, 40 and 47 mm. The bars have hot-rolled thread over the full length of the bar. Thus, there is no reduction of the working load due to reduction of the diameter and notch effect. The bars can be cut at any point and coupled together on-site.

Smooth bars

DYWIDAG’s smooth bars are manufactured in high tension steel with a yield/ultimate strength of 950/1050 N/mm2 in the dimensions ø32 and ø36 mm. The bars can be delivered with up to 0.5 m rolled thread which has a high fatigue strength. Bars and thread can be delivered in required length.

Accessories

Nuts, couplers, anchorages, anchor plates, corrugated steel or plastic ducts etc. are all standardized and ensure full load. The accessories are made of St.37 or St.52 and thus fully weldable.

Post-tensioning systems with strands

DYWIDAG’s post-tensioning systems are used all over the world for all applications in post-tensioned constructions. The strands are mainly 0.62″ with a yield/ultimate strength of 1670/1860 N/mm2. The strands can be greased and PE-sheathed. The max. working load is 75% of the ultimate load (short overload to 80% is allowed). The strand system with accessories is approved for post-tensioning of bridges, tunnels, buildings, civil applications etc.

Feel free to contact us – we are ready to help you with soil anchors