Wide range of vacuum dryers

Customer specific solutions

Bachiller has great experience and competence in designing vacuum dryers, thus ensuring that the equipment gives an optimum process for the customer.

Test center

The company has modern facilities with a laboratory for the testing of processes prior to the production of customers’ order.

Service

Customers are supported throughout the life cycle of the equipment and are guaranteed delivery of necessary spares etc.

Quality and certifications

Bachiller’s equipment and production comply with the following: ISO 9001:2015, ASME U and U2 seals, HP0 certificate in accordance with AD-2000 Merkblatt, Module H & H1 in accordance with PED, A2 license in accordance with Chinese SQL and ISO 14001:2015.

Bachiller is specialized in the design and construction of process equipment, particularly within mixing and drying technology, for the pharmaceutical, chemical, petrochemical, fine chemical, cosmetic and food industries. Bachiller offers a wide range of high-quality process equipment and solutions. These include Nutsche filters and vacuum dryers. Bachiller cooperates with the customers to develop customized solutions and new processes. Bachiller designs and manufactures all this equipment in-house while monitoring the entire manufacturing process, from the calculation and design, steel construction, mechanization, mechanical polishing and commissioning / start-up.

Bachiller is ISO 14001 certified and has great focus on reducing the company’s total carbon footprint. They can help customers with environmentally optimal solutions.

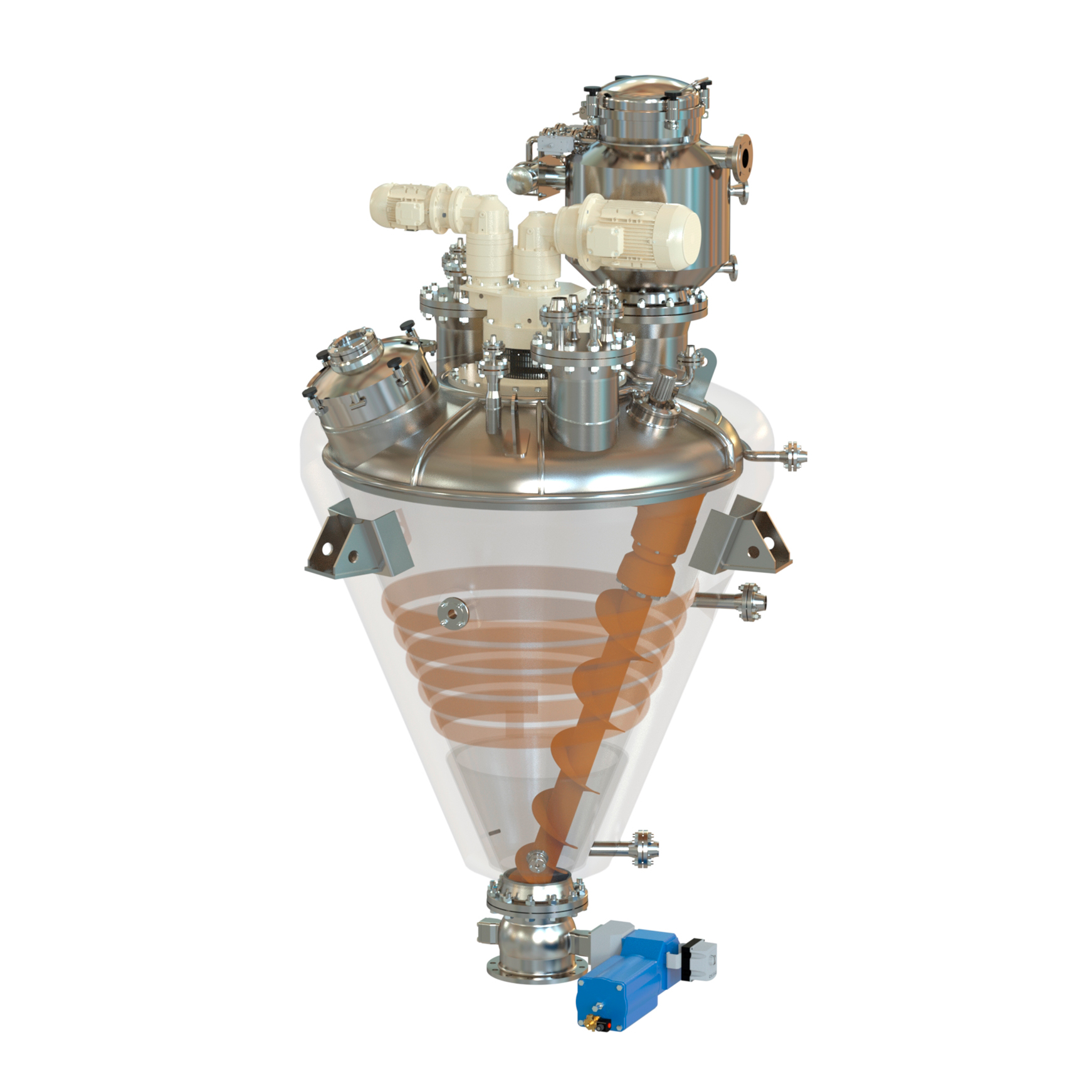

Vertical conical dryers MCV-NS/NCS

The vertical conical vacuum dryers MCV-NS have a sanitary design which lives up to cGMP requirements and which can be FDA validated. They are suitable for vacuum drying of all kinds of wet products such as crystalline and amorphous products. The MCV-NS is a fully heated vacuum dryer – incl. the paddle.

The main advantage of the MCV-NS is that the agitation shaft is not continuous, and once the product is dry, the conical shell can easily be emptied without any valuable product residues left.

An important advantage of the MCV-NCS, based on the NS, is that transmission to the mixing shaft is performed by means of a grease-free belt which guarantees compliance with health requirements because no grease can accidentally contaminate the product.

The MCV-NS can be delivered in volumes from 30 to 10,000 L and in accordance with the ATEX directive.

Learn more about the vertical conical dryers MCV-NS/NCS here

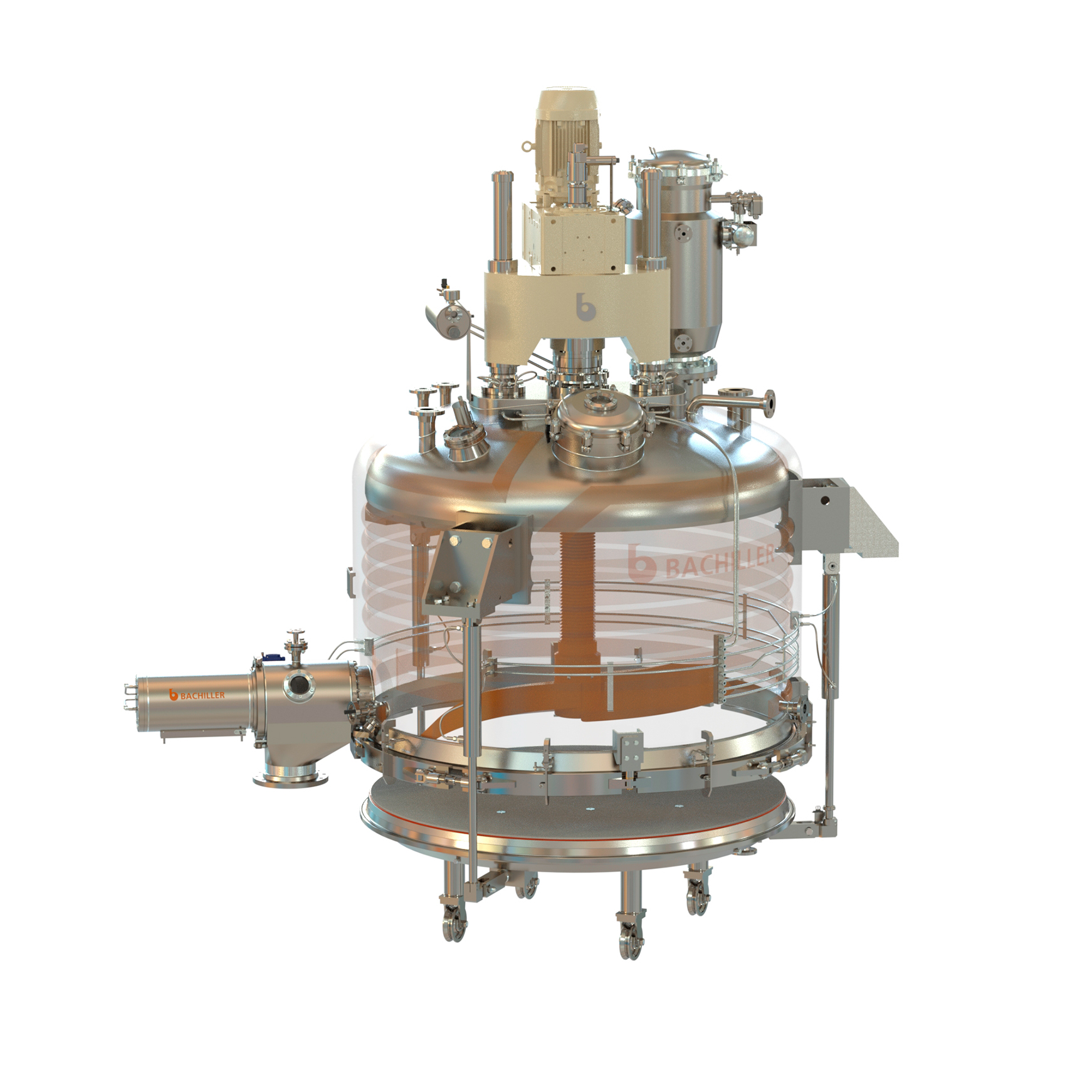

Nutsche filters/dryers FNB-S

The Nutsche filters model FNB-S are Bachiller’s Nutsche filters/dryers. They can be used for a wide range of applications, incl. filtration processes, in which it is necessary to work batchwise without switching products, for later vacuum drying.

The Nutsche filters/dryers are designed for a wide range of operations such as extraction, filtration, pressing, washing, decolouration and vacuum drying. The operating principle for a Nutsche filter is based on a shell designed for pressure and vacuum, with a removable bottom, equipped with a filter.

Bachiller has designed its Nutsche filter/dryer to minimize downtime. This e.g. includes automatic opening/closing of the filter bottom, easy replacement of filter mesh as well as Bachiller’s own Superclamp which reduces man hours for opening/closing as well as maintenance.

The Nutsche filters can be supplied with filtration surfaces from 0.07 up to 15 m2 and for capacities from 19 to 15,000 L.

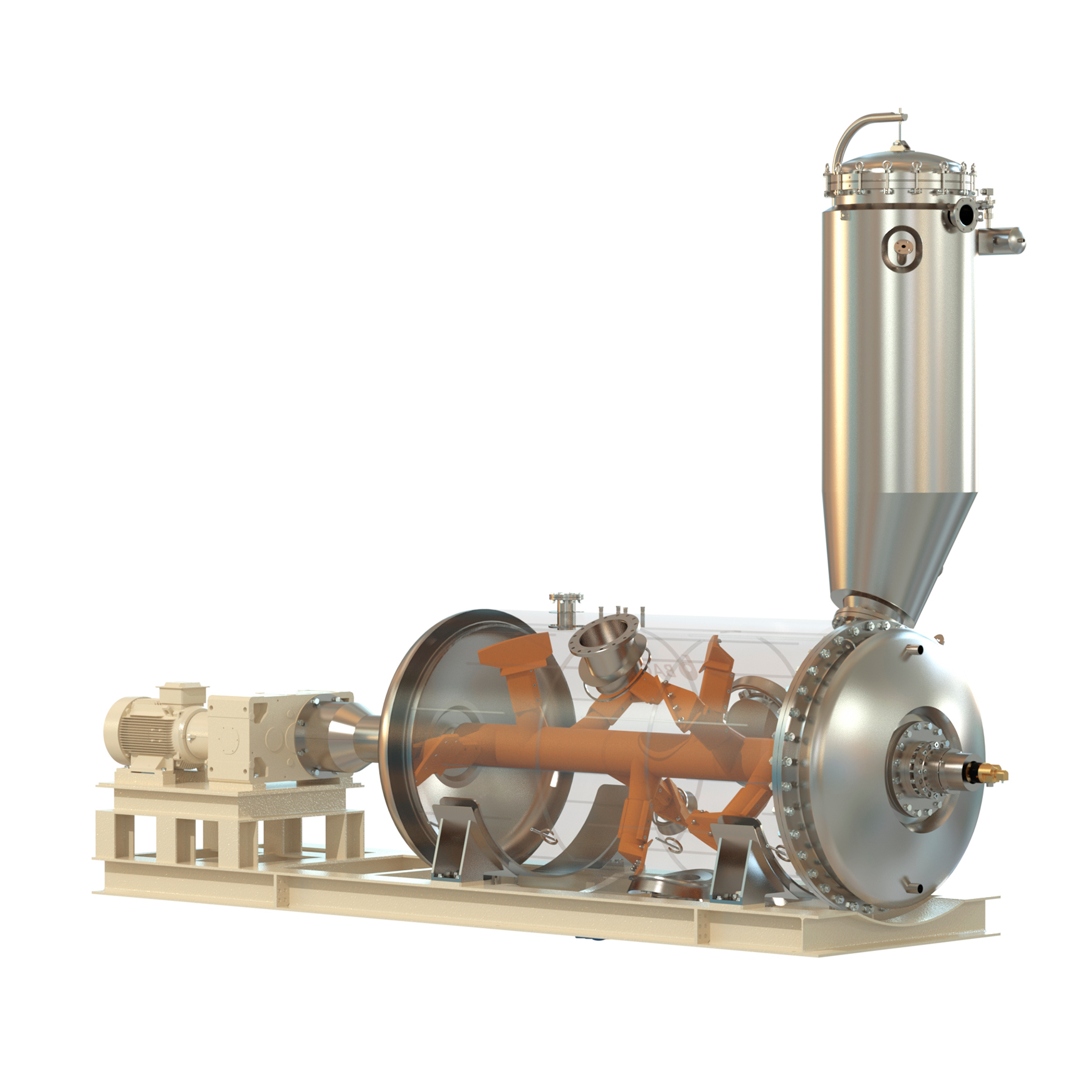

Horizontal paddle dryers SANIDRY SHV

The SANIDRY SHV is a dryer specially designed for sanitary batch applications, designed in accordance with cGMP recommendations. It is provided with a large access door, allowing full and easy cleaning and maintenance operations.

Heating is applied to the whole vacuum dryer, including the shaft and agitation, if necessary, which contributes to dynamic drying, resulting in the complete absence of cold spots. Shaft tightness is obtained by means of Bachiller’s special sanitary mechanical seal.

The vacuum dryer is placed on a supporting bedframe, in which a separating plate can be attached in order to segregate the clean process zone from the drive that remains in the technical area.

The SANIDRY vacuum dryers have a long list of optional equipment, such as bag filters, chopper-type lateral lump breakers, CIP/SIP systems and test valves. And they can of course be delivered in accordance with the ATEX directive if required.

The SANIDRY vacuum dryers are offered in a range of sizes suitable for capacities from 50 to 10,000 L.

Learn more about the horizontal paddle dryer SANIDRY SHV here

Horizontal paddle dryers PADDLEDRY MHT-S

The rotary dryers are specially designed for vacuum drying applications with high mechanical requirements, liquids with complicated texture, very viscous liquids or products going through pseudo-plastic phases. It is also completely suitable for hightemperature drying processes.

The agitator shaft is supported in both ends of the mixing chamber, and tightness is obtained through mechanical seals. The agitator rotates at very low speed with a very high agitation torque, which makes it especially appropriate for difficult products.

MHTR-S can be supplied with choppers for lump breaking. Furthermore they can be supplied with the following optional equipment: heated shaft and paddles, with test valve and in accordance with the ATEX directive.

Available in volumes from 10 to 30,000 L.

Learn more about the horizontal paddle dryer PADDLEDRY MHT-S here

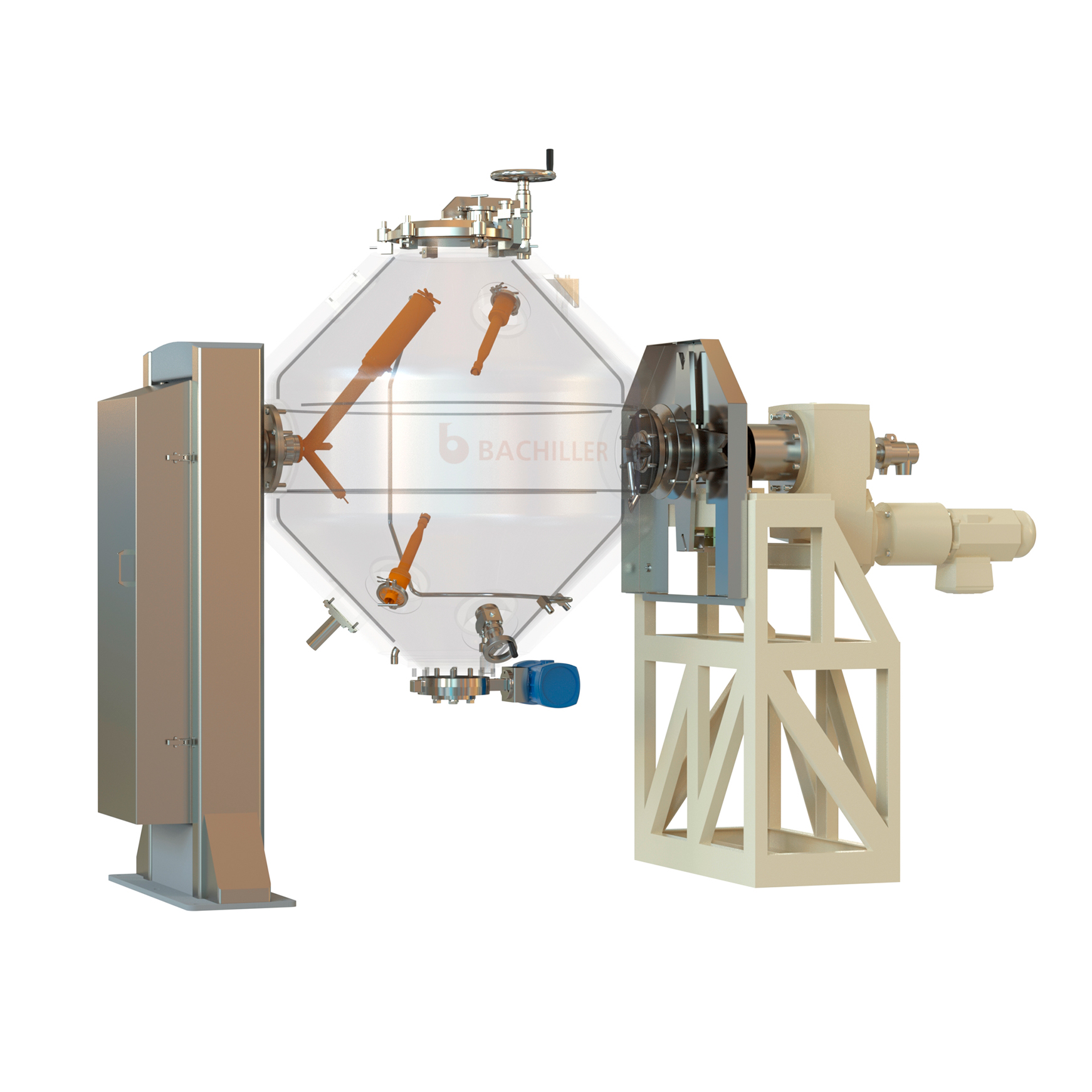

Biconical Vacuum Dryers MBC-S

The biconical rotary vacuum dryers are commonly used in applications involving fragile products which require keeping their morphology unharmed. They are especially recommended for hygienic solutions due to the absence of internal components which could eventually interfere with cleaning.

The MBC-S is a batch dryer and is delivered in a standard version fully heated and insulated.

The MBC-S can be equipped with a removable filtration system for easier cleaning. Furthermore the following options can be mentioned: lump breaking choppers, CIP/SIP systems, test valves and in accordance with the ATEX directive etc.

The MBC-S dryer is available in sizes from 30 to 30,000 L.

Spiral Dryers SDV

The spiral vacuum dryers have a sanitary design and a maximized heated surface, that is applicable for all kinds of wet products such as crystals, amorphous products or pastes which need to be completely discharged after drying. They have a compact and vertical design.

The vertical spiral vacuum dryers are rotating at moderate speed to obtain an upwards flow of the product which thus gets contact with the heated walls. This drying principle allows complete volume mixing/drying and is gentle with the products.

The design allows for complete unload of the drying chamber and a delumping device is available if required. These vacuum dryers are inspection friendly and generally require limited maintenance.

They are available in capacities from 50 to 30,000 Land in accordance with the ATEX directive.

Feel free to contact us – we are ready to help you with vacuum dryers

David Bøgh

Sales Manager and product specialist

Email: db@aagechristensen.dk

Mobile: +45 21 30 32 20